New Guidelines For Fiber Optic Training And Certification

When FOA was founded in 1995, fiber optics had already been in commercial use for about 15 years, long distance OSP networks were still being replaced by fiber optics, metro networks were just beginning to be converted to fiber optics and fiber-to-the-home was a distant dream. Premises applications were limited to a multimode LAN backbones where speeds or distances were too much for Cat 5 as well as some video links to remote security cameras.

Over its first two years, a group of FOA advisors met to create the requirements for technician certification that became the CFOT, Certified Fiber Optic Technician. Those requirements became the KSAs, the knowledge, skills and abilities required to be a certified fiber optic technician. The KSAs in turn became the basis of developing curriculum for training and CFOT certification testing.

In 1995, a technician was expected to be able to work with both singlemode and multimode fiber. They needed to be familiar with loose tube and armored OSP cables as well as zipcord and distribution indoor cables. Splicing skills in both mechanical and fusion splicing were needed. Termination of singlemode fibers was done by splicing singlemode fibers to factory-made pigtails. Multimode termination was mostly done using adhesives and polishing, using heat-cured epoxy, anaerobic adhesives or the 3M Hot Melt connectors. Testing involved connector inspection and cleaning, power measurements and optical insertion loss with a light source and power meter. Long distance networks would also be tested with OTDRs.

At that time, some tools and instruments like visual fault locators, fusion splicers and OTDRs were less common and quite expensive, often too expensive to be included in a school’s training equipment inventory, so they were often described in class, maybe with a video, and demonstrated by the instructor or a salesperson.

Over the last 25 years much has changed in fiber optics. Network speed, driven by the growth in Internet traffic, has become thousands of times faster, wavelength-division multiplexing has become mainstream, FTTH (fiber-to-the-home) enabled by PON (passive optical network) technology has become one of top applications for fiber optics, along with connecting wireless cell sites. The expansion of wireless networks, traffic control systems, utility grid management, data centers, etc. has led to lots more fiber applications.

Virtually all this growth is in singlemode fiber. Ribbon cables, microcables and high-fiber count cables are being used extensively. Even data centers which utilize some of the fastest networks and have changed to singlemode to avoid replacing cables frequently when equipment speeds are upgraded. LANs are adopting PONs, joining DAS (cellular networks inside buildings) to convert many premises cabling systems to singlemode. Multimode fiber is not extinct, but certainly an endangered species.

Installation techniques and components have changed too. Few techs terminate multimode with adhesive/polish connectors in the field anymore. First it was replaced by mechanical splice connectors in the field, what we called prepolished/splice connectors, but now it’s fusion SOCs – splice-on connectors – that are becoming the termination method of choice. They were first seen in data centers where it’s not unusual to have 100,000+ terminations in the cable plant. Now we have low-cost fusion splicers and SOCs that make it the logical – and often lowest cost – termination choice.

For testing, instruments like visual fault locators (VFLs) have become really cheap so everyone can have one for troubleshooting. Power meters are more automated and lower cost, as are laser test sources. Interestingly, multimode test sources with LEDs are in short supply as the 850 and 1300 nm LEDs they need are become harder to get because the market for them in fiber optics has disappeared; they have been replaced by VCSELs which are not good as test sources.

When FOA started, OTDRs were very expensive and primarily limited in use to long distance OSP networks. Now OTDRs are not only less expensive and capable of testing most networks, but they are highly automated. Manufacturers tout the ability of their OTDRs to use AI (artificial intelligence) to set up the instrument and interpret traces. That’s a logical approach, since the instruments are highly complex and hard to understand, therefore few techs ever learn how to properly use one.

FOA believes that fiber optic technician training courses need to reflect the real world, and as technology and applications change, training must change also. Today’s CFOT needs to be competent in working with singlemode fiber, fusion splicing, SOCs and the equipment used today for installation and testing. Hands-on labs should focus on this current technology to ensure competent techs.

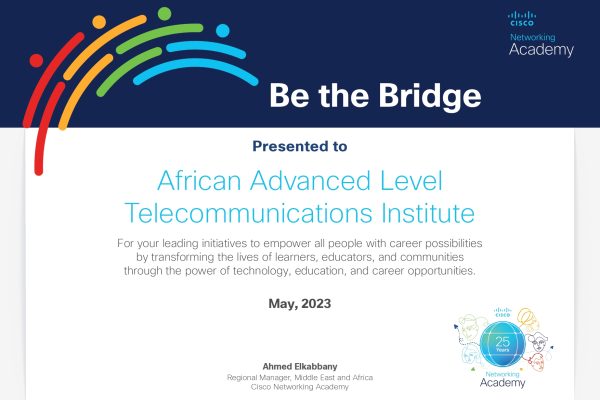

FOA is creating new course guidelines for approved schools such as AFRALTI to follow to ensure their training fits current technician needs. These new guidelines will be ready for use in 2022.